细胞疗法和基因疗法将成为医疗保健的新标准,但依旧不定、复杂且难以一致性生产。

作为一个行业,我们正在创建将有助于加快疗法开发、批准和交付的集体知识与经验,但努力降低商品成本的同时,我们仍有一些瓶颈待解决:

- 令工艺中变异性最小化的最佳方式是什么?

- 您是否能从 RUO 顺畅过渡到 GMP?

- 您可以如何将生产从实验室纵向扩展到临床生产乃至大规模生产?

为了克服这些挑战并且自身为监管审批做好准备,您需要助力您加速开发且使工艺标准化的高品质原材料、尖端生产解决方案和精密分析。

Bio-Techne 的技术和服务可以量身定制满足您的需求,实现顺畅、高效开发与生产细胞疗法和基因疗法。自身的集体智慧和专业技能把我们充分塑造成您的合作者和长期合作伙伴。无论您是正在开发免疫细胞疗法、再生疗法或基因疗法,我们都垂手以备塑造医疗保健的未来。

携手共进,我们可以解锁未来的疗法。

免疫细胞疗法

展现出可比性和可重复性对于推进免疫细胞疗法至关重要。了解您疗法的作用机制和量化关键质量属性 (CQA) 是复杂的并且可能是代价不菲的临床挫折和监管挫折源。

我们高品质 GMP 级原材料配合精密分析技术,使您能够提供稳健、可靠数据, 以确定概念验证、确保监管批准并加快到达患者的时间。

这些可扩展的灵活解决方案可帮助您适应变动不居的监管环境。我们还在这里将灵活性嵌入您的工艺,从而您可以轻松调整自身工艺以满足不断变化的要求。

这些可扩展、灵活解决方案使您能够从实验室顺畅转移到临床并适应变动不居的监管环境:

- 无动物源性 RUO 级和 GMP 级蛋白质

- 非病毒基因递送系统

- 免疫细胞培养解决方案

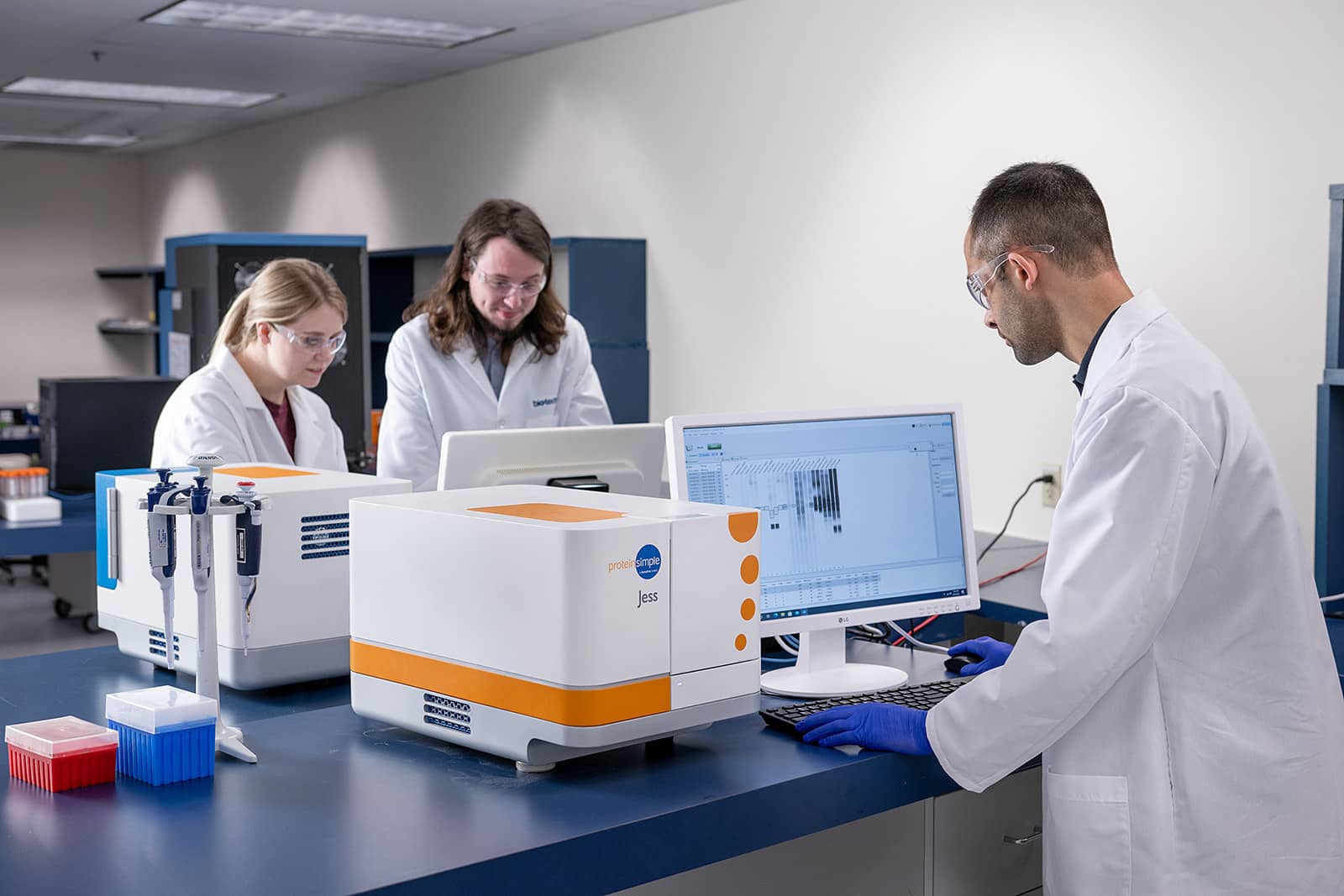

- 自动化分析仪器

再生医学

在开发再生疗法时,让变异性最小化是成功的基础。借助一致、可扩展性解决方案配合可靠供应高品质原材料,我们可以助您开辟一条道路通向安全、改变生活的疗法。

我们认识到您扩大生产时面临的挑战——这就是为何我们所有的再生医学解决方案都以可扩展性为核心所创建的原因。

我们提供量身定制的解决方案,以贯穿整个再生医学开发工作流程帮助您,包括:

- 无动物源性 RUO 级和 GMP 级蛋白质

- 非病毒基因递送系统

- 干细胞和类器官培养解决方案

- RUO 级和 GMP 级小分子

- 空间生物学平台

- 自动化分析仪器

基因疗法

实现安全有效的转基因递送属于基因疗法开发者面临的挑战。病毒载体的固有复杂性致使难以贯穿整个开发和生产阶段一致地表征这些载体。

因此,我们为关键质量属性分析提供精密分析工具,以确保疗法安全、高品质、一致和有效。

这些可定制、灵活、快速的检测和分析系统贯穿整个基因疗法开发工作流程提供您所需的高特异性、自动化和可靠结果:

- 用于体内监测的空间生物学平台

- 自动化载体分析和表征解决方案

- 免疫分析

信心十足地纵向扩展与横向扩展

将生产从实验室纵向扩展到临床生产是所有细胞疗法和基因疗法要克服的主要障碍。大规模生产基于细胞的复杂疗法是一项涉及冗长过程和庞大数量的巨大挑战,但我们旨在让您更容易完成这个过程。

为了更易纵向扩展免疫细胞疗法项目,我们已携手 Fresenius Kabi 和 Wilson Wolf,为您呈献 ScaleReady™——一项旨在用简化、标准化和流畅化解决方案让免疫细胞疗法更快到达临床的合作——这些解决方案已用于获批上市的 CAR-T 药物疗法中。

可扩展性是我们所有细胞疗法和基因疗法解决方案的核心,并且可以用我们全面的 GMP 级材料产品组合进一步提高。使用提供业界出众品质、一致性和可靠性的原材料,实现满负荷生产并最大限度降低风险。

从 RUO 向 GMP 过渡更顺畅

导引从研发到临床生产的转变过程带来独有挑战,尤其在面临从 RUO 级原材料到 GMP 级原材料的变更时。为了促进顺畅过渡,我们为细胞疗法和基因疗法提供诸多 GMP 级材料,包括细胞因子和生长因子,这些材料均在我们新的专业化无动物源性 GMP 生产设施内生产。

每种 GMP 级产品都直接对应于我们的 RUO 级无动物源性形式,根据 ISO 9001 认证以及《美国药典》(USP) 和欧洲指南生产。我们对 RUO 级材料和 GMP 级材料采取的细致方法确保您有一个平稳过渡过程,助力您保证原材料供应一致且质量始终如一。

细胞疗法与基因疗法定制解决方案

您的细胞与基因疗法生产工艺是否有特定的体积要求? 为了确保您的工艺尽可能高效运行且最大限度减少浪费,我们可以瓶装和包装批量试剂,以满足您对我公司所有 RUO 级材料和 GMP 级材料的精确工艺要求。我们的定制解决方案包括:

- 定制 GMP 级蛋白质和抗体开发

- 细胞培养基生产服务

- 小分子和化学服务

- 定制免疫分析开发

- 定制流式细胞术试剂

利用稳健的质量控制和分析工具改进产品洞察力

让您的细胞疗法产品与基因疗法产品通过监管批准并上市,这要求准确、可重现地测试关键质量属性。

我们的分析性产品与服务按照极高的品质保障措施生产,让您能够自信前行并且确保细胞疗法产品与基因疗法产品符合您的精确质量、纯度和性能要求。

- 通过易用、自动化解决方案简化并加速工作流程

- 用单一平台分析多个 CQA

- 贯穿整个工作流程实现高灵敏度细胞表型分析

- 密切监测产品疗效和毒性

细胞与基因疗法按需教育资源

我们致力于按每种可能方式推进细胞与基因疗法研究,这是我们为何精心策划了一系列按需教育资源,引导您完成细胞与基因疗法之旅的原因。在我们的资源中心,饱览各种教授性文章、教授性内容和应用说明。

通过我们引人入胜的细胞与基因疗法网络研讨会,尽情遨游智慧海洋,这些网络研讨会涵盖本领域挑战、最佳实践,同时聚焦于最新进展。错过了关键课程? 不用担心!我们的按需资源库确保您总是消息灵通,按自己的步调学习。